| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : Brictec

Model Number : brictec

Certification : CE; ISO

Place of Origin : China

MOQ : 1set

Price : US$26000-28500

Payment Terms : L/C,D/A,D/P,T/T,Western Union,MoneyGram

Delivery Time : 40DAYS

Equipment Introduction: Clay Bricks Packing Brick Packaging Clay Bricks Packing Brick Packaging

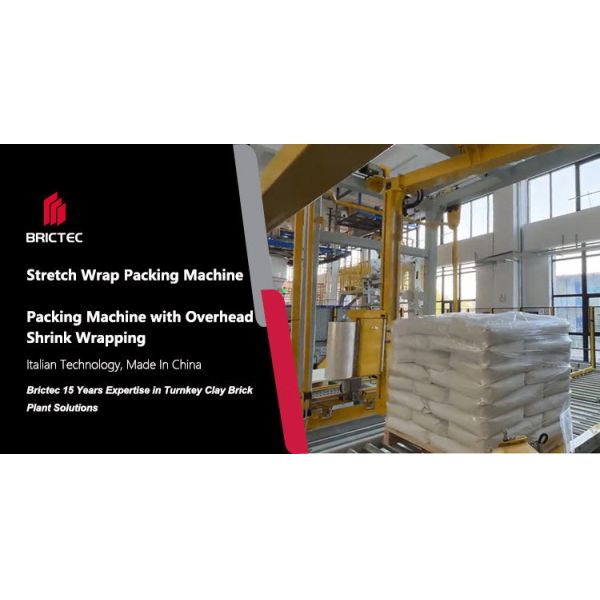

Stretch Wrap Packing Machine is an automated device used for wrapping products by stretching film and winding it around goods or pallets to achieve a secure, protective, and aesthetically pleasing packaging effect. It is widely used in logistics, warehousing, building materials, food, and other industries. Clay Bricks Packing Brick Packaging

Product Types for Packaging: Clay Bricks Packing Brick Packaging Clay Bricks Packing Brick Packaging

1.Logistics and Warehousing: Suitable for palletized goods and logistics packages.

2.Building Materials Industry: Suitable for building materials such as clay bricks, cement, and tiles.

3.Food Industry: Suitable for food, beverages, fruits, and vegetables. Clay Bricks Packing Brick Packaging

4.Other Industries: Suitable for home appliances, chemicals, machinery, and other industries.

Features and Advantages: Clay Bricks Packing Brick Packaging Clay Bricks Packing Brick Packaging

1. High Efficiency and Automation: Fully automated operation reduces manual intervention and increases packaging efficiency.

2. Cost Savings: Optimizes film usage to reduce packaging material costs.

3. Strong Protective Performance: The film has properties such as waterproofing, dustproofing, and moisture resistance, effectively protecting the products. Clay Bricks Packing Brick Packaging Clay Bricks Packing Brick Packaging

4. Easy Operation: User-friendly interface and simple operation process make it easy to use.

5. High Safety: Stable operation and compliance with safety standards ensure safe operation.

Film Materials Used: Clay Bricks Packing Brick Packaging Clay Bricks Packing Brick Packaging

1.LLDPE(LLDPE Film): The most commonly used material, with good tensile strength and elasticity.

2.PVC (PVC Film): Suitable for packaging that requires higher transparency.

3.Other Materials: Other materials such as nylon film can be selected based on specific needs.

Wrapping Speed and Packaging Efficiency: Clay Bricks Packing Brick Packaging

1. High-Speed Wrapping: Modern stretch wrap packing machines can achieve a wrapping speed of 20-30 revolutions per minute, depending on the model and settings. Clay Bricks Packing Brick Packaging

2. Efficient Packaging: By optimizing the wrapping path and film stretching, the machine can complete packaging quickly, improving production efficiency. Clay Bricks Packing Brick Packaging

3. Customized Settings: Users can adjust the wrapping speed and film stretch according to the product size and packaging requirements. Clay Bricks Packing Brick Packaging Clay Bricks Packing Brick Packaging

Packing Machine with Overhead Clay Bricks Packing Brick Packaging

Shrink Wrapping Clay Bricks Packing Brick Packaging

Recommended Packaging for Clay Fired Bricks Clay Bricks Packing Brick Packaging

|

|

Automatic Stretch Wrap Packing Machine for High Efficiency Brick Packaging with Cost Savings and Strong Protective Performance Images |